|

|

One Stop Solution For Your Drilling Need enquiry@drillmacindia.com, 9911196897 , 9711196897 | |||

|

|

|

|||||

|

|

|

|

ABOUT US |

| Drillmac’s deep roots in the manufacturing of drilling rigs started back in era and since then continuously improved rig design

by raising the pull-up capacity, enhancing safety, optimizing performance and minimizing environmental impact

Drilling contractors objectives and conditions are constantly changing and require different solutions to achieve results.

Drillmac rigs are available in a wide range of specifications in order to fit custom configurations and capabilities.

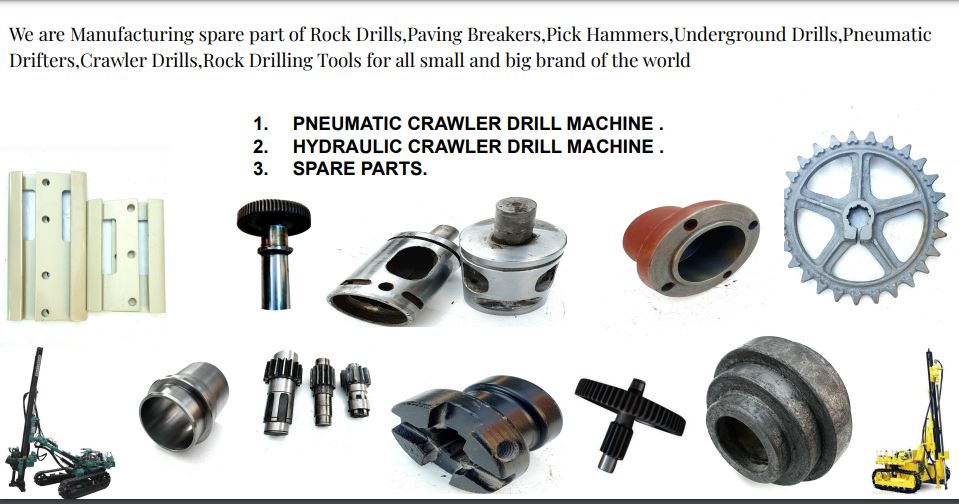

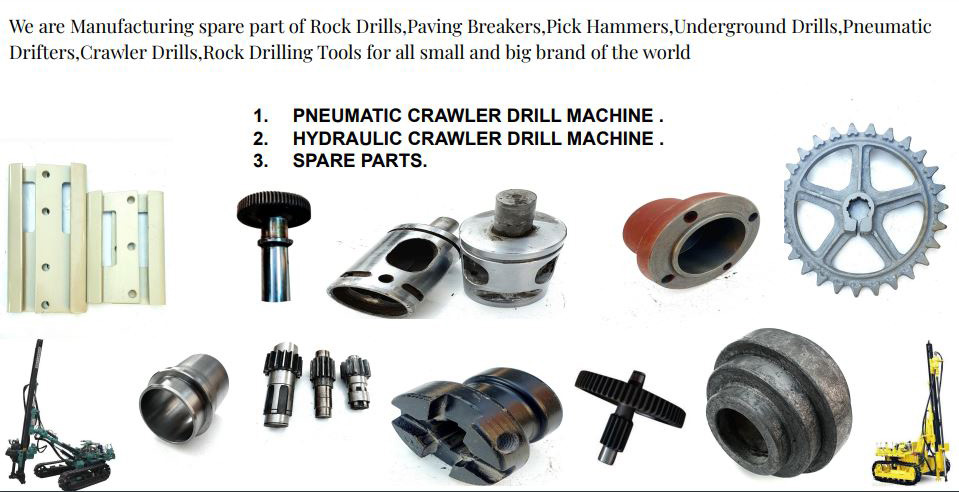

DrillMac is a seasoned OEM supplier with a strong sales & service setup in over 25 countries internationally and now starting its

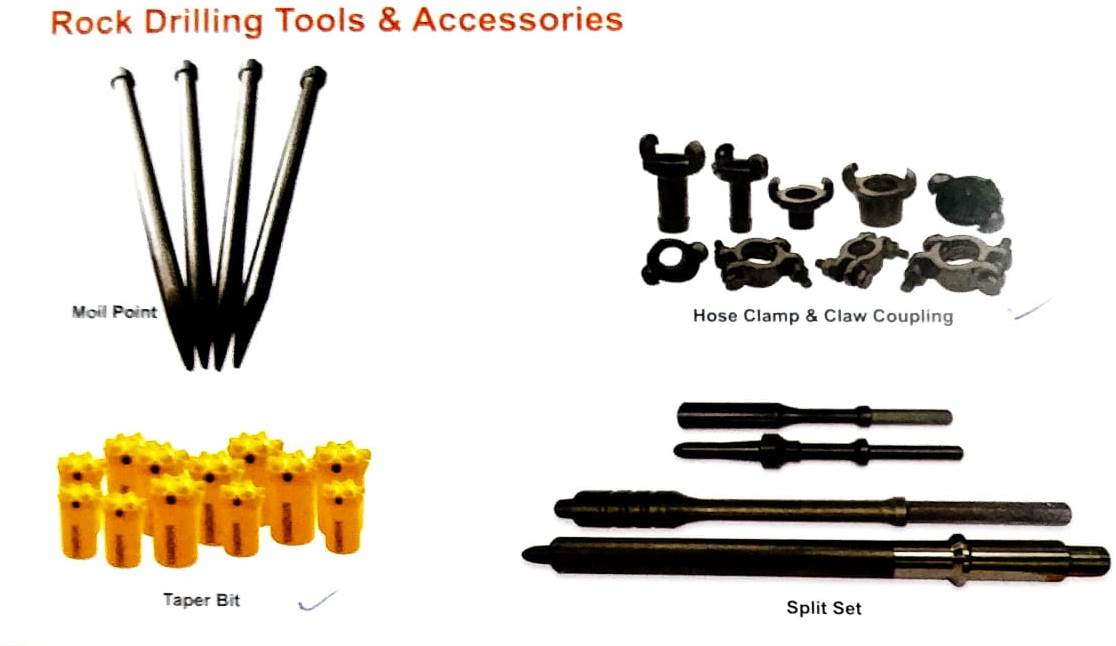

journey in India . We are proud of our industry-leading line of crawler drills,drill rigs, jackhammers, underground rockdrills,

DTH hammers, drifters, demolition tools, drill bits, drilling tools, and accessories With a customer-centric mindset, DrillMac

provides single-window contract manufacturing services to our customers worldwide. We perform rapid product development

& volume manufacturing for our OEM customers located in the USA, Canada, South Africa, Sweden, Belgium, and Italy

DrillMac has an extended set up in more than 25 countries across the world, including Canada, USA, South Africa, Mexico, Peru,

Brazil, Zambia and Zimbabwe. The company is further planning to expand its distribution centers in Australia, India, Ecuador,

Chile, Columbia, Russia, Kazakhstan, Kenya, Tanzania, Botswana, Dubai and the UK.

The organization has stood as a successful distributor in the international market. Apart from that, it had also been serving

domestic customers efficiently. More than 50 distributors are working across the subcontinent to cater to the needs of the

domestic market.| Read More |

|

|

Machining |

| We boast a wide array of sophisticated machining lines consisting of high-precision CNC lathe, multi-axis CNC mill (HMC & VMC), gundrill and multi-step broach. Machine tools are from reputed makers including Mazak ( Japan), Cross Huller (Germany), Haas (USA), Verinelli (Italy) to name a few. In-line quality assurance is performed at every step. We also have our own tool room for custom fixturing and gauging. |  |

|

Grinding |

| We pride ourselves in our world-class grinding setup capable of maintaining dimensions within 3 microns. The grinding line includes state-of-the-art equipment including Studer (Switzerland) Universal CNC grinder, Micromatic (India) Cylindrical CNC grinder with in-process gauge, WMW (USA) NC ID grinder, universal NC grinders. We also have a line of Sunnen (USA) honing machines. In-line air gauging is implemented for quality assurance. |  |

|

Surface Treatment |

| We offer an array of surface treatment options, including shot blasting, blacking, and painting. These processes enhance tool life and provide it with an appearance as per customer specifications. |  |

|

Assembly & Testing |

| Assembly & testing is carried out by our young and energetic team on custom-built assembly platforms and test rigs. Each assembled drill is tested for torque, BPM, and air consumption. Upon successful testing, every drill is issued a unique test certificate ensuring its quality. |  |

|

Tool Room |

| Our ultra-modern and state of the art tool room under a single roof is capable of making intricate jigs and fixtures, receiving gauges, special cutting tools, special purpose machines, broaches, re-sharpening of special tools, etc. Our wide spectrum of sophisticated equipment includes all the latest and advanced machines which are dedicated to tool room activities and product development. The tool room is supported by design professionals providing innovative designs and drawings for a specific requirement.Facilities available in the tool room: Tool Room LathesDeckel Maho Milling MachineEDM MachineHorizontal Milling Machine with D.R.O.Optical Profile GrindingSurface GrinderCylindrical GrinderCoordinate Measuring MachineAir Compressor for Testing & try out. |  |

|

Quality Control |

| To achieve customer satisfaction by supplying “zero defects” products and timely deliveryTo ensure planned results and continual improvements To increase productivity by utilizing the latest technologies and reducing downtimeTo ensure training of employees as per defined targets, training needs and requirements Quality Assurance. Drillmac is ISO 9001:2015 certified by TUV Nord. Our endeavor is to constantly monitor and improve our processes to ensure the highest quality products. Highly experienced quality inspectors working with a wide range of sophisticated instruments and special gauges test all components for dimensional, metallurgical, and functional performance. Periodic internal and external quality audits are performed for continuous quality improvements. |  |

|

Promoter's Detail |

|

Porush Dev Panchal :- 9911196897, 9711196897, |

||||||

|

|

OUR RANGES |

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

WHY US |

||||||

|

|

OUR INFRASTRUCTURE |

||||||

|

|

OUR TEAM |

|||||||||

| |||||||||

|

|

|

CONNECT WITH US |